I. Introduction

The creation of tote bags is an artistic endeavor that integrates design, material selection, and manufacturing techniques. It’s more than just putting a few pieces together; it’s an obsession with accuracy and care. This article will provide you a thorough grasp of this industry by walking you through every step of the bag-making process, from creative thoughts to exhibiting the finished product.

II. Design Phase

⑴Establishing Design Concepts: Determine the design concept based on market demands, trends, and customer feedback.

Creating a large tote bag that meets the changing demands of customers is more important than its visual appeal. Design concepts are established by carefully balancing consumer feedback, prevailing trends, and market demands. Let’s examine each facet to comprehend how designers go across this complex terrain.

a. Market Demands:

Research and Analysis:

To comprehend the present needs and gaps in the work tote bag market, conduct in-depth market research.

Examine the preferences, actions, and purchases of your customers.

Identifying Niche Markets:

Examine possible specialized markets or unexplored areas within the larger leather tote bag industry.

Take into account how changing lifestyles, travel patterns, and demographics affect customer demands.

Competitor Analysis:

Examine rivals to find winning design cues and points of differentiation.

Examine industry leaders and up-and-coming companies to determine the competitive environment.

b. Trends:

Fashion and Style Trends:

Keep an eye on the style and fashion trends that affect the creation of travel handbags.

To predict future trends, work with fashion experts or forecasters.

Material and Technology Trends:

Keep up with developments in manufacturing methods and materials.

Examine cutting-edge and environmentally friendly materials that complement current market trends.

Cultural and Global Influences:

Think about how cultural influences and international travel patterns may affect your taste in design.

To reach a wide audience, embrace inclusivity and diversity in design.

c. Customer Feedback:

Gathering Customer Input:

Make a conscious effort to get input using focus groups, surveys, and internet resources.

For up-to-date information, keep an eye on consumer evaluations and social media conversations.

Analyzing Feedback:

Examine consumer input to find recurring themes, issues, and needs.

Give top priority to comments that support the overall design objectives and brand identity.

Engaging with the Community:

Create a community centered around your business to help people feel like they belong.

Have direct discussions with clients to learn about their particular requirements and expectations.

Designing cross body leather bag requires a dynamic interplay between knowing what the market wants, following trends, and aggressively seeking out feedback from customers. Through careful manipulation of these components, designers can produce a bag that not only satisfies functional needs but also speaks to the shifting tastes of the market. In the next stages, these ideas become concrete designs that skillfully combine creativity and functionality in the realm of cross body designer bag workmanship.

======================

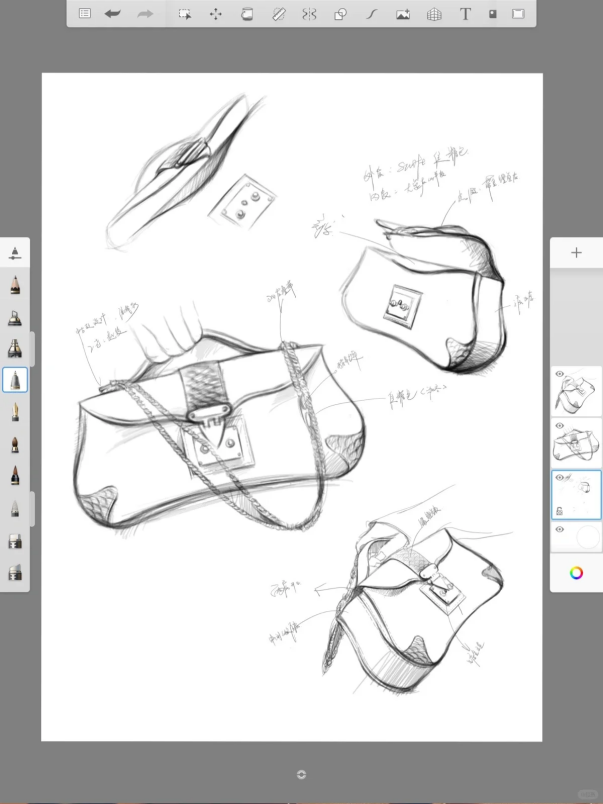

⑵Hand Sketching: Designers create hand-drawn sketches outlining the basic shape and structure of the bag.

A bag starts out as an idea on paper before it is made of material. Handdrawn sketches are a crucial step in the design process when designers bring their concepts to life. We’ll look at the designers’ process as they use the deft technique of hand-drawn sketches to establish the fundamental form and structure of ladies designer handbags.

a. The Creative Space:

Setting the Scene:

To stimulate creativity, designers frequently begin in a calm, inspirational environment.

A clean, well-lit space can help you concentrate better when you’re sketching.

Essential Tools:

Differently hardened pencils to provide various effects of shade and lines.

Use high-quality erasers to make repairs without causing damage to the paper.

Use sketchbooks or fine-quality paper sheets to record ideas.

b. The Sketching Process:

Conceptualization:

Designers plan out the general concept and function of the evening handbags before they ever put pen to paper.

Functionality, the intended audience, and any special features are taken into account.

Initial Rough Sketches:

Start by creating free-form, crude sketches to experiment with various dimensions and forms.

At this point, ideas can be expressed freely and without exact accuracy.

Refinement and Detailing:

Select the most promising ideas and give them careful refinement.

Pay special attention to any embellishments that improve the design, as well as seams and closures.

c. Precautions and Challenges:

Avoiding Over-Complication:

Designers need to be careful not to overcomplicate the initial concepts even though detail is crucial.

Concentrate on communicating the main ideas and structure.

Flexibility for Iterations:

It should be simple to make changes and revisions to sketches.

It is important for designers to accept that the creative process is not rigid.

d. Collaboration and Feedback:

Sharing Ideas:

Share sketches for feedback with other team members or stakeholders to work together.

Various points of view can be incorporated into the design through collaboration.

Incorporating Feedback:

To enhance and strengthen the sketches, take into account suggestions from mentors or other team members.

Remain receptive to constructive feedback.

e. Digital Tools (Optional):

Transitioning to Digital Platforms:

Some designers might decide to use tablets or graphic design tools to digitize their hand-drawn sketches.

Additional exploration and refining are possible with digital technologies.

An important step in the design of a black tote handbag is the production of hand-drawn sketches. Equipped with pens and an imaginative mind, designers convert intangible concepts into concrete depictions of shape and purpose. These sketches lay the foundation for the subsequent phases of bag craftsmanship through meticulous conception, collaborative effort, and iterative improvement. With each stroke of the pen, the designer gets closer to creating a one-of-a-kind, useful masterpiece.

⑶Detailed Design: Refine the sketches through iterative modifications, including material selection, color coordination, and detailing.

These illustrate the process of iteratively editing and refining the sketches while designing leather tote bags for women and other bags.

a. Sketching

A basic sketch of the leather bags for women must be made by the designer in the early phases of the project. To make assessing the bag’s functioning and look simple, the sketch should depict all of the bag’s angles and details. At this point, designers should let their imaginations run wild and experiment with as many various aspects and combinations of designs as they can.

b. Material selection

Your crossbody tote bag’s material selection will determine how well it looks and feels. Based on the intended use of the bag and the demands of the consumer, designers must select the right materials. For instance, designers should use materials like nylon or polycarbonate that are lightweight, waterproof, and wear-resistant for bags that will be carried for extended periods of time. Designers might use premium synthetic leather or real leather for crossbody handbags that need to project an upscale image.

c. Color matching

An essential component of bag design is color. The target market and client needs must be taken into consideration by designers when deciding how to mix colors in bags. Coordination with the surroundings and compatibility with the contents of the bag must also be taken into account when matching colors. For instance, to enhance the emotional appeal of travel bags, designers can select color schemes that correspond with the destination or time of year.

d. Detail processing

One of the main elements that determines the quality of crossbody tote is its detail processing. Every little aspect of the bag, such as the zippers, fasteners, stitching, lining, etc., must be considered by the designers. You must take into account these details’ durability, functionality, and appearance when working with them. For instance, when choosing a zipper, take into account its smoothness, robustness, and convenience of use; similarly, when designing a lining, take into account its comfort, durability, and ease of cleaning and maintenance.

e. Repeated modification and optimization

The designer still needs to make constant changes and improvements to the sketch after finishing the aforementioned steps. To guarantee that the finished product satisfies consumer demands and market expectations, this entails processing and refining the bags’ look, functionality, materials, colors, and details. Designers should focus on the following issues in particular:

Appearance improvement: Enhance and optimize the look of bags in accordance with consumer demands and industry trends. In order to make the bags more appealing and unique, this involves working on their forms, lines, patterns, and details.

Function enhancement: Refine and optimize the bag’s features in light of real-world use cases and user input. To enhance storage and organization convenience, this involves adding internal accessories like pockets, compartments, and organizers. It also entails adding external accessories like handles and hanging accessories to enhance portability and comfort.

Material optimization: Optimize and process bag materials in accordance with consumer and real-world demands. This entails selecting materials that are stronger, lighter, and more ecologically friendly. The material’s surface can also be treated to increase its texture and stain resistance.

Color matching innovation: Develop and improve bag color matching based on consumer demands and market trends. This entails experimenting with different color schemes and styling to make them more eye-catching and unique, as well as selecting the appropriate color schemes for various events and seasons.

Exquisite processing of details: To guarantee the bag’s quality and usefulness, every detail is handled and refined. This involves improving the quality and functionality of features like zippers, fasteners, stitching, and linings; additionally, the details can be tailored to meet the unique requirements of the client.

In summary, sketch optimization and iterative revision are essential steps in the bag design process. To create products that satisfy consumers, designers must focus on market trends and client wants. They must also start with a variety of factors, including look, function, material, color, and details, and never stop trying new things.

⑷Prototype Production: Create a prototype to validate the feasibility and aesthetics of the design.

Creating prototypes is an essential phase in the design process of large black tote bag, as it allows you to confirm the design’s viability and visual appeal. The steps involved in creating bag samples, including where to find the necessary supplies and extras, are described in full below.

a. Select the main material

Selecting the primary material is the first step in creating a large designer tote bags sample. Based on design specifications and market positioning, designers must select the right materials. Common materials for a bag’s main body include nylon, polyester fiber, leather, and imitation leather. You must take into account various aspects when making your decision, including the material’s cost, wear resistance, waterproofness, and mobility.

b. Select accessories and auxiliary materials

You must select the proper auxiliary and accessory materials, such as zippers, fasteners, stitching, lining, etc., in addition to the primary material. The choice of these accessories and accessories must also take into account elements like cost, quality, durability, and functionality. For instance, there must be smooth zippers, sturdy fasteners, durable stitching, and easily cleaned and comfy linings.

c. Sample production

You can begin creating bag prototypes after deciding on the primary material and any necessary extras. Typically, this procedure involves assembly, sewing, cutting, and other steps. Designers must keep an eye on every stage of the procedure to make sure that samples adhere to quality standards and design specifications.

d. Quality inspection and optimization

The completed lightweight crossbody bag samples must go through quality assurance testing, which includes durability, functionality, and appearance testing. In order to guarantee that the finished product can satisfy consumer expectations and market demand, designers must promptly make any necessary alterations and optimizations.

e. Evaluation and improvement

Lastly, the sample needs to be assessed and improved by the designer. To guarantee that the finished product can accomplish the anticipated design effect and market performance, this entails processing and enhancing the luggage’s appearance, function, materials, and details. In order to keep products competitive and appealing, designers must also constantly innovate and optimize based on market trends and customer input.

In summary, creating baggage prototypes is an essential first step in confirming the design’s viability and aesthetic appeal. For the finished product to satisfy consumer expectations and market demand, designers must focus on material selection, accessory quality, and every facet of the production process. In order to keep items appealing and competitive, designers must also constantly develop and optimize their work.

III. Material Selection and Preparation

⑴Primary Materials:

Typically employ materials like canvas, leather, and nylon. Choose the right materials keeping the design requirements in mind.

Below is a detailed summary of the uses, advantages, and disadvantages of the main materials used in luggage:

a. Leather material:

Usage: High-end bags, including briefcases, backpacks, and purses, are frequently made from leather materials. Leather is a material that is frequently utilized in luxury products and fashion because of its natural texture and appearance.

Advantages: Leather is soft and comfortable to the touch, has a natural texture and appearance, and is simple to dye and texture. Leather materials also offer a lengthy service life, strong wear resistance, and waterproof qualities.

Disadvantages: The manufacture process is intricate and involves several steps, and leather supplies are expensive. Furthermore, the leather material is readily distorted and has low impact resistance because of its soft texture.

b. Textile materials:

Usage: Rucksacks, nylon travel bags, and other mid-range and low-end baggage are frequently made from textile materials. Textile fabrics are extensively employed in outdoor sports and travel because of their strength and light weight.

Advantages: Textile materials can tolerate some wear and stretching and have good resilience to rips and tears. Textile materials are also appropriate for manufacturing baggage, such as travel bags, that need to have a specific carrying capacity since they have good moisture absorption and air permeability.

Disadvantages: Compared to leather materials, textile materials are less luxurious and have a more commonplace touch and appearance. Furthermore, textile materials need to be waterproofed during processing because of their generally weak waterproof qualities.

c. Synthetic materials:

Usage: Low-end baggage, such plastic backpacks and synthetic leather purses, is frequently made from synthetic materials. Young people and fashionistas frequently employ synthetic textiles because of their low weight and ease of processing.

Advantages: Synthetic materials come in a variety of colors and designs, are lightweight, and are simple to work with. Furthermore, synthetic materials are waterproof and have good wear resistance, making them suitable for a wide range of applications.

Disadvantages: Synthetic materials tend to feel cheap and still lag far below real leather and textile materials in terms of texture and appearance. Furthermore, synthetic materials are more likely to chip and are less impact-resistant.

⑵Accessory Materials:

Include zippers, buckles, handlebars, etc. Select these based on the type of bags and design specifications.

Wheels, handles, zippers, linings, outside pockets, trolleys, and other attachments are frequently used with bags. These are the functions, benefits, and drawbacks of different accessories:

a. Trolley: One of the key pieces of luggage equipment that makes handling and transporting bags easier is the trolley. Tie rods’ material, load-bearing capability, and ease of use determine both their benefits and drawbacks.

Advantages: Users can choose the carrying technique that works best for them by simply adjusting the height of the draw rod. In addition, the tie rods can give the luggage more stability so that it doesn’t distort or sustain damage while being carried.

Disadvantages: Poor quality tie rods are more prone to issues like breaking or bending, which will reduce their usefulness. Additionally, one must take into account how convenient it is to use the pull rod. Additionally, if the pull rod’s action is excessively intricate or challenging, the user will experience inconvenience.

b. Wheels: One of the most essential equipment for moving luggage is a set of wheels, which are utilized to move across the surface. Wheels have benefits and drawbacks related to their composition, flexibility during rotation, and noise level.

Advantages: Excellent wheels may guarantee luggage moves smoothly and lessen noise and friction. Additionally, some wheels include a shock-absorbing quality that helps lessen the impact of the luggage’s vibrations and bumps on people’s bodies.

Disadvantages: Poor wheel quality will make wear and jamming more likely, which will reduce the usefulness of the wheels. Additionally, while driving, some wheels may make loud noises that interfere with other people’s sleep or ability to function.

c. Handle: One of the key pieces of luggage equipment that makes handling and transporting luggage easier is the handle. The material, load-bearing capability, comfort, and other aspects of the handle determine its benefits and drawbacks.

Advantages: Users may effortlessly carry the bag thanks to the nice grip that the premium handle offers. In order to keep the luggage from becoming distorted or broken while being carried, the handle can also offer extra support for it.

Disadvantages: Inappropriate design or poor handle material might make the handle difficult to grip or difficult to use. Furthermore, certain handles could be inadvertently struck or overload, leading to issues like shattering.

d. Zipper: One of the most crucial pieces of baggage equipment is the zipper, which is used to open and close the bag. The smoothness, longevity, and ease of maintenance of zippers are their key advantages and downsides.

Advantages: Users may effortlessly open and close the bag thanks to long-lasting and smooth zippers. Additionally, some zippers incorporate anti-riot features, which might improve a bag’s safety.

Disadvantages: A poorly made zipper or one that is not utilized correctly might lead to damage or jams. Additionally, the user might have to invest more time and money in replacing or repairing the zipper if it is difficult to fix.

e. Lining: One of the key components of the bag is the lining, which improves comfort and serves to safeguard the contents within. The material, comfort, and durability of linings determine their benefits and drawbacks.

Advantages: The premium lining can offer a soft touch and protective purpose, enabling customers to confidently carry and utilize the bag. Additionally, certain linings are waterproof, which might improve the bag’s waterproof capabilities.

Disadvantages: Poor quality lining material or an irrational design could result in an uncomfortable touch or inadequate protection. In addition, overloading or unintentional impacts may harm some liners.

f. Outer pocket: One of the key components of the bag is the outer pocket, which may be utilized to hold small objects or expand the bag’s storage capacity. The outer pocket has benefits and drawbacks that are related to its sensible construction, storage, and security.

Advantages: Users may easily store small goods and reach them at any moment thanks to the high-quality outer pocket’s ample size and storage. Simultaneously, some outside pockets—like waterproof pockets—also serve as safety features that can improve the security of objects.

Disadvantages: Items may be difficult to put in or take out of the outside pocket if the design is illogical or the storage capacity is inadequate. Furthermore, certain exterior pockets might present safety risks, including potentially scratchable zippers.

⑶Sewing Thread:

Select threads that complement the main materials to guarantee both strength and style.

The following factors should be taken into account when selecting baggage sewing thread:

a. Material: Large chemical fiber thread, cotton thread, and nylon thread are common materials for bag stitching thread. varied materials have varied qualities in wires; for example, cotton has good moisture absorption and air permeability, nylon has great strength and resistance to wear, and big chemical fiber has tight texture and longer durability. Thus, when choosing wires, keep the bag’s intended function and environment in mind.

b. Specifications: Typically, the number of strands and count are used to describe bag sewing thread parameters. The thread’s thickness is indicated by the number of strands, while its density is indicated by the count. In general, the wire gets thinner the more strands and thinner the count, and vice versa. The type and function of the sewing machine, together with its model and characteristics, must all be taken into account while choosing thread for bag construction.

c. Color: The design and intended use of the luggage must be taken into consideration while choosing the color of luggage sewing thread. For instance, light-colored wires can be used to create stylish and new backpacks, while dark-colored wires can be utilized to create luggage like travel bags that need concealed stitching.

d. Quality: Another crucial factor is the sewing thread used for baggage. While low-quality wires are more likely to break or wear out, high-quality wires function better and are more durable. It is important to verify the certification seals and quality requirements of the wires you choose.

When choosing bag sewing thread, you need to pay attention to the following points:

①To make sure the thread has enough strength and longevity, pay attention to its density and texture.

②To ensure the bag’s overall attractiveness and quality, pay attention to how the thread color and material match.

③To make sure the cord has enough durability and safety, pay attention to its certification criteria and quality.

④To ensure improved performance and longevity, select the right wire based on the intended use and the specifics of the bag.

⑷Material Preparation:

Selected materials are cut and polished to get them ready for manufacture.

A number of material preparation tasks, such as material selection, cutting, and polishing, are necessary prior to the manufacture of bags.

Prior to anything else, it’s important to ascertain which materials—main, auxiliary, and accessory materials—are needed for the luggage. Make sure the materials are safe and of high quality, and choose them based on the bag’s intended function as well as the design specifications.

You then have to get to work cutting. The chosen materials will be cut to the necessary length in accordance with the design drawings and the real requirements of the luggage. When cutting, accuracy and neatness are crucial in order to guarantee the quality and effectiveness of the procedures that follow.

Certain materials require sanding after they have been cut. For instance, to increase the smoothness and feel of leather goods, you must use sandpaper or a polishing machine to remove burrs and uneven areas. To make metal items more beautiful and resistant to corrosion, they must also be ground and polished.

Lastly, some more supplies, including pull rods, buttons, sewing thread, zippers, etc., must be ready. To guarantee the quality and functionality of the bag, these materials must be chosen and processed in accordance with the real requirements of the bag.

To put it briefly, enough material preparation work, including as material selection, cutting, and polishing, must be done before baggage production can begin. These jobs safeguard the materials’ quality and safety and get them ready for next production steps.

IV. Production Process

⑴Cutting: Using the design pattern as a guide, cut the main materials into the necessary sizes and shapes.

The cutting procedure is a crucial step in the creation of custom tote bags. Cutting is the process of dividing and cutting materials into certain sizes and shapes in accordance with design specifications. The procedure and safety measures for cutting bags are as follows:

a. Layout: The materials are placed on the platen in a reasonable manner in accordance with the specifications of the design drawings and luggage components. When arranging, it’s important to consider the position and dimensions of each component as well as the materials’ grain, color, and texture.

b. Marking: Mark the cutting piece’s outline on the material precisely with a paper knife or marking needle in accordance with the typesetting specifications and design drawings. When creating patterns, it’s important to focus on the precision and smoothness of the lines as well as the space left between each element.

c. Cutting: Cut and divide the material in accordance with the indicated outline using scissors or a cutting machine. When cutting, it’s important to focus on keeping your strength and speed steady and avoiding issues like burrs and breakage.

d. Inspection: Examine the cut materials for quality issues, such as burrs, damage, etc., and determine if the pieces’ dimensions and shapes satisfy the specifications. If issues arise, they must be resolved and modified promptly.

e. Marking: To make it easier to identify and manage the operations that follow, mark the cut materials and provide information about the names, serial numbers, and other components of the bags.

The following things need to be considered when cutting a leather tote:

①To guarantee the cutting effect and quality, the chosen scissors or cutting equipment should be chosen in accordance with various materials and thicknesses.

②To prevent issues like burrs or breakage, constant strength and speed must be maintained during the cutting operation.

③To prevent quality issues, perform a quality inspection on the cut materials to make sure the dimensions and forms of the cut pieces comply with the specifications.

④To aid in identification and process management, it is imperative to mark bag components with their name, serial number, and other relevant information.

In summary, a crucial step in the bag-making process is the cutting procedure. It is imperative to consider the rationale of the equipment selection and process flow, as well as to guarantee the quality and efficiency of cutting.

⑵Sewing: Stitch the cut materials together to make the basic construction of the bags, either by hand or with the aid of sewing machines.

Le reusable tote bags sewing process includes the following steps:

a. Preparation work: Prepare the necessary materials and accessories, such as fabrics, linings, zippers, buttons, etc., in accordance with the bag’s design specifications. To guarantee that the stitching process proceeds without a hitch, simultaneously make sure that the cutting instruments and sewing machine are operating normally.

b. Cutting: Cut the cloth into the appropriate form and size using scissors or a cutting machine in accordance with the design drawing. To guarantee the caliber and effectiveness of ensuing procedures, pay close attention to precision and organization.

c. Sewing: Sew the lining and cut fabric in accordance with the specifications of the design. Various sewing methods and techniques, including as flat seams, welt seams, double top-stitching, etc., are utilized depending on the styles and requirements. In addition, be mindful of the density and tightness of the stitches to prevent issues like broken threads and skipped stitches.

d. Assembly: Put the sewed bag components together, making sure to install the handles, buttons, zippers, and other parts. To guarantee the bag’s overall elegance and solidity, pay close attention to the placement of each part and the caliber of the connections.

e. Inspection: Examine the sewn bags for quality issues, such as broken threads and skipped stitches, and make sure every component satisfies the design specifications. If issues are discovered, they must be resolved and modified promptly.

When sewing large designer tote bags, you need to pay attention to the following points:

①To guarantee accurate and effective sewing, use the proper sewing machine needles and sutures.

②Keep precision and neatness in mind during cutting to prevent excessive mistakes that could lower the quality of the final product.

③Keep an eye on the density and tightness of the stitches as you sew to prevent issues like skipped stitches and broken threads. In order to maintain the bag’s overall elegance and firmness, pay close attention to how each component’s joints and corners are treated.

④To prevent issues like loosening or falling off, pay close attention to each component’s location and the strength of the connections during the construction process.

⑤To guarantee the general excellence and aesthetic appeal of the bags, meticulous attention to detail and the resolution of quality concerns are given during the inspection process.

To guarantee the overall quality and attractiveness of the bags, the bag sewing process necessitates paying close attention to details and quality issues, choosing the right materials and tools, and using the right sewing methods and techniques.

⑶Assembling: Assemble accessory materials (e.g., zippers, buckles) according to design requirements.

The following steps are included in the bag assembly process:

a. Prepare materials: Accomplish the necessary materials (fabrics, linings, zippers, buttons, etc.) based on the bag’s design specifications.

b. Creating the bag’s exterior shell: To create the bag’s outer shell, sew the fabric and lining together in accordance with the design specifications.

c. Install buttons and zippers: Attach buttons and zippers to the luggage shell, making sure that their placement and quality adhere to the specifications of the design.

d. Assemble internal components: Assemble the bag’s interior components, including pockets and compartments, together in accordance with the design specifications, making sure that every item is positioned correctly and that the connections are of high quality.

e. Quality inspection: Examine the assembled bags for quality issues, such as broken threads and skipped stitches, and make sure every component satisfies design specifications. If issues are discovered, they must be resolved and modified promptly.

f. Arrangement and packaging: To assure the bags’ overall firmness and beauty, arrange and package the ones that passed the inspection.

During the weekender tote assembly process, you need to pay attention to the following points:

①To guarantee the quality and elegance of your baggage, employ the right supplies and equipment, as well as the right assembly procedures and techniques.

②When creating the luggage shell, be mindful of the fabric’s texture and the level of stitching to prevent issues like broken thread and skipped stitches.

③When attaching zippers and buttons, be mindful of their positioning and quality to prevent issues like loosening or falling off.

④To guarantee the overall elegance and solidity of the bag, pay close attention to the placement of each internal component and how the connections are handled during assembly.

⑤To guarantee the general excellence and attractiveness of the bags, care is taken during the quality inspection process to address any concerns that may arise.

⑥To maintain the integrity and aesthetic appeal of the bag, be mindful when packing and organizing to prevent contamination or damage to the exterior and interior components.

⑷Quality Check: Make sure that all manufacturing stages are in conformity with design specifications and quality standards by conducting thorough quality inspections.

During bag production, the quality inspection procedure typically consists of the following steps:

a. Material inspection: The materials used in production undergo quality examination prior to manufacturing to guarantee that they fulfill design specifications and quality standards. The material’s texture, color, size, and other characteristics are all included in the inspection content.

b. Cutting inspection: In order to make sure that the cut components’ size and shape adhere to the design specifications, the cutting accuracy is verified during the cutting process. Additionally, inspect the materials for damage or defects.

c. Sewing inspection: The density, tightness, neatness, and other aspects of the stitches are examined during the stitching process. To guarantee excellent stitching and a lovely appearance, it’s also important to inspect the corners and joints of each component.

d. Assembly inspection: Make sure that all of the parts are installed correctly during the assembly process, including the handles, buttons, zippers, and other parts. Verify that each component’s connections are solid and in the right place.

e. Finished product inspection: Following production, the product is examined for quality, including dimensions, functionality, and appearance. The products undergo concurrent durability and safety testing.

The following are the salient features and inspection reports at various inspection stages:

①Material inspection: Pay close attention to whether the material’s texture, color, size, and other characteristics match the design specifications and quality standards. Details on the materials used, quality requirements, inspection findings, etc., should all be included in the inspection report.

②Cutting inspection: Pay close attention to the cutting precision to make sure that the cut pieces’ dimensions and form adhere to the design specifications. Additionally, inspect the materials for damage or defects. Shape and size of the cut pieces, tools and methods used for cutting, inspection findings, etc. should all be included in the inspection report.

③Sewing inspection: Pay close attention to the stitches’ density, tightness, neatness, and other characteristics. To guarantee excellent stitching and a lovely appearance, it’s also important to inspect the corners and joints of each component. Suture density and tightness, stitching techniques and equipment, inspection findings, etc. should all be included in the inspection report.

④Assembly inspection: Pay close attention to how each component is installed, especially the handles, buttons, zippers, and other parts. Verify that each component’s connections are solid and in the right place. The inspection results, installation location, stiffness of each component, assembly techniques and tools, and other information should all be included in the inspection report.

⑤Finished product inspection: Pay close attention to examining the final items’ quality, taking note of details like size, function, and appearance. The products undergo concurrent durability and safety testing. The findings of functional tests, durability and safety tests, appearance and dimensional measurement data, etc., should all be included in the inspection report.

We can guarantee that the bag production process satisfies design specifications and quality standards by conducting quality inspections at the aforementioned phases. This will enhance the caliber of the final product and increase customer satisfaction.

V. Inspection and Packaging of Finished Products

⑴Visual Inspection:

Check the bag’s look to make sure it satisfies design requirements and is free of flaws like scratches or uneven colors.

The following phases are often involved in the appearance inspection process of a finished large black tote:

Examine the bag’s overall appearance to see if it satisfies the quality and design standards. Including the bag’s dimensions, color, texture, and so forth.

Examine the bag’s surface thoroughly to look for any stains, scratches, color variations, distortion, or other issues. These issues could deteriorate the bag’s surface or make using it less enjoyable.

Examine the interior of the bag to see if there are any issues, such as very long thread ends, crooked stitching, or uneven zippers. These problems could have an impact on the bag’s longevity and quality.

To ensure the bag satisfies the requirements, compare the design drawings and sample bags. Including the bag’s composition, hue, dimensions, and so forth.

To see if there are any issues, such as light leakage or transmission, shine a flashlight on the bag’s surface. These issues could have an impact on the bag’s usability and aesthetic appeal.

Shake the bag several times to make sure there are no loose parts or strange noises. The bag’s quality and safety may be impacted by these problems.

The bag will be thoroughly examined in accordance with the design and quality specifications to ascertain whether it satisfies factory standards.

To guarantee that the quality and appearance of the product satisfy the design specifications and quality standards, the visual inspection of finished extra large tote bags for work must be thorough and rigorous, examining the product from multiple angles.

⑵Dimensional Inspection:

Verify the bag’s measurements against standards to make sure it doesn’t affect usage by being excessively big or undersized.

We will discuss the crucial step of dimensional inspection, in which the size of the bag is closely examined to make sure it complies with requirements and strikes the ideal balance between form and function.

a. Defining Standard Dimensions:

Industry Standards:

·Recognize and abide by the bag dimensions set forth by the industry.

·Standard sizes could change depending on the kind of bag—handbags or backpacks, for example.

User-Centric Approach:

·When choosing standard measurements, take into account the end customers and their requirements.

·Depending on what they are going to be used for, bags can have different standard dimensions.

b. Tools for Dimensional Inspection:

Measuring Instruments:

·Make use of accurate measurement instruments including digital calipers, tape measures, and rulers.

·To get correct readings, make sure these instruments are calibrated on a regular basis.

Templates and Guides:

·For fast visual assessments, create templates or guidelines based on conventional proportions.

·Using templates makes it easier to spot deviations from the target size when doing an examination.

c. Dimensional Inspection Process:

Length, Width, and Height:

·Measure the bag’s height, width, and length in accordance with the guidelines.

·Verify that the dimensions are symmetrical and consistent.

Internal and External Compartments:

·Check the inside compartments for proper alignment and sizing.

·Make sure no outside pockets or features interfere with the overall measurements.

d. Impact on Usability:

User Comfort:

·Verify that the bag’s measurements comply with ergonomic guidelines to ensure user comfort.

·Think about things like carrying convenience and weight distribution.

Functionality:

·Consider the effect that the bag’s size will have on its intended use.

·For example, a backpack should be large enough to hold essentials without getting cumbersome.

e. Addressing Deviations:

Iterative Process:

·If discrepancies are found, think about adjusting dimensions through an iterative design approach.

·Get user and stakeholder input to determine the effects of suggested changes.

Maintaining Aesthetic Balance:

·Make sure you don’t sacrifice the bag’s overall attractiveness when modifying its measurements.

·Make an effort to strike a healthy balance between form and purpose.

The compass that leads a bag from design to functionality is dimensional inspection. Through painstaking measurement and strict adherence to specifications, designers guarantee that every bag is not only an aesthetic pleasure but also a useful addition for its owners. The procedure is more complex than just math; it involves striking the ideal balance between the bag’s dimensions and usability to give its users the best possible experience. When it comes to creating bags, accuracy is the ultimate measure of excellence.

⑶Functional Inspection:

Check the bag’s functioning, including the pocket’s fit and the zipper’s smoothness.

A personalized tote bag’s actual worth is determined by its usefulness; it is more than just a chic accent. The painstaking procedure known as functional inspection examines each component one by one to ensure a flawless user experience. We’ll go through all of the specific steps involved in functional inspection in this post, including how to create thorough inspection reports and discuss important topics like pocket appropriateness and zipper smoothness.

a. Zipper Smoothness:

Visual Examination:

·Examine the zipper visually for any obvious flaws, alignment issues, or anomalies.

·Verify that the zipper’s teeth are intact and positioned correctly.

Operational Test:

·To evaluate the zipper’s longevity and smoothness, open and close it many times.

·Look for any obstacles, problems, or changes from the intended functionality.

Zipper Stops:

·Make sure the zipper stops are firmly in place on both ends.

·Make sure the slider cannot come loose from the zipper chain by using the stops.

b. Pocket Suitability:

Size and Capacity:

·Verify that the pockets fit the function for which they were designed.

·Verify each pocket’s capacity to make sure it satisfies design requirements.

Closure Mechanism:

·Examine the pocket closing system, including the zippers, snaps, and other fasteners.

·Make sure closures function properly and safely.

Internal Organization:

·Check interior pockets for correct alignment and arrangement.

·Make sure that pocket placement does not jeopardize the structure as a whole.

c. Straps and Handles:

Attachment Points:

·Check for tight stitching at the strap and handle attachment locations.

·To make sure the straps are securely fastened, tug the device.

Adjustability:

·Make sure the locking mechanisms on adjustable straps are secure and easy to modify.

·Make sure the handles are comfortably sized and firmly fastened.

d. Special Attention Areas:

Seams and Stitching:

·Check for consistent stitching and tight fasteners at every seam.

·Particular care should be given to wear-prone areas and stress points.

Hardware and Accessories:

·Check if buckles, D-rings, and studs are functional and aligned properly.

·Make sure that any ornamental elements are fastened firmly.

e. Inspection Reports:

Documenting Findings:

·Make a thorough inspection report for every bag, recording everything that was discovered during the functional examination.

·Add pictures to help illustrate any flaws or problems.

Quality Standards Checklist:

·Create a checklist based on quality standards to make sure that all functional elements meet design requirements.

·Refer to the checklist before making changes to the production process in the future.

An effective inspection is the defender of a bag’s functionality. The makers guarantee that every bag works flawlessly and looks excellent by carefully inspecting every part, including pockets, straps, and zippers. The method defines the dependability and utility that people anticipate, going beyond aesthetic appeal. When it comes to the complex realm of bag workmanship, a product’s longevity is determined by its attention to useful details.

⑷Packaging:

The bags that pass inspection should be packaged to improve overall appearance and safeguard them throughout transit.

A travel tote’s journey doesn’t stop at creation; it continues with the cautious packaging that keeps it safe until the user receives it. This post will discuss the careful packing of completed bags, which not only protects them throughout transit but also improves their appearance overall for a striking unboxing experience.

a. Selection of Packaging Materials:

Protective Outer Packaging:

·To keep bags safe from the outdoors, choose sturdy outer packaging materials.

·Depending on the kind and size of bag, take into account alternatives such cushioned envelopes or corrugated cardboard boxes.

Internal Cushioning:

·Use internal cushioning to protect the bag from any impacts, such as air cushions, foam, or bubble wrap.

·Make sure cushioning is positioned carefully to shield sensitive regions.

b. Branding and Presentation:

Branded Packaging:

·Include branded components, including taglines, logos, or distinctive patterns, in the packaging design.

·The brand identity is extended by the packaging itself.

Inclusion of Marketing Materials:

·Place promotional offers, thank-you cards, and product catalogs inside the package as marketing collateral.

·Include components that strengthen the user’s bond with the brand to improve the unboxing experience.

c. Securing the Bag:

Dust Covers or Sleeves:

·To keep the bag’s surface free of dust and scratches while being transported, use dust covers or sleeves.

·These covers can also give the packaging a hint of refinement.

Secure Fastenings:

·To avoid movement during transit, make sure the personalized tote bags are firmly tied inside the package.

·For stability, use ties, straps, or specially made inserts.

d. Quality Control:

Final Inspection:

·Verify each wrapped product one last time to make sure it lives up to expectations.

·Check to make sure all parts—accessories and promotional materials included—are present.

Barcode and Labeling:

·Label and barcode every package for simple tracking and identification while in transit.

·Labels should provide relevant information such as care directions.

e. Sustainable Packaging Practices:

Environmentally Friendly Materials:

·To support environmental objectives, think about utilizing eco-friendly and sustainable packaging materials.

·Use packaging to convey the brand’s dedication to sustainability.

Minimalistic Packaging:

·Adopt a simple, minimalistic design philosophy for packaging to cut down on waste and encourage simplicity.

·Pay attention to the crucial components that enhance both appearance and safety.

The last caress a bag receives before it is used is during packaging. Manufacturers transform promotional tote bags from a product into a well-curated experience by carefully choosing materials, adding branding features, and making sure fastenings are secure. The packaging process aims to create an unforgettable unboxing experience that symbolizes the brand’s dedication to quality and beauty, in addition to providing protection. When it comes to bag workmanship, the packaging is the last piece that brings the whole thing together.

VI. Conclusion and Outlook

We now have a better understanding of the entire bag-making process thanks to the introduction of these five steps. Every stage, from developing design concepts to finishing product inspections, calls for exacting craftsmanship and stringent supervision. The bag manufacturing sector is developing and evolving in response to the growing demands of consumers for higher-quality and more fashionable bags. In order to satisfy growing market and consumer needs, bag production methods will in the future place an increased emphasis on energy efficiency, environmental sustainability, and smart technologies.